PS-30 Profile Sensor

PS-30 Profile sensor

uncomplicated and flexible

for precise measurements and inspection tasks

PS-30 Profile sensor

uncomplicated and flexible for precise measurements and inspection tasks

Higher production efficiency and improved product quality

Higher production efficiency

and improved product quality

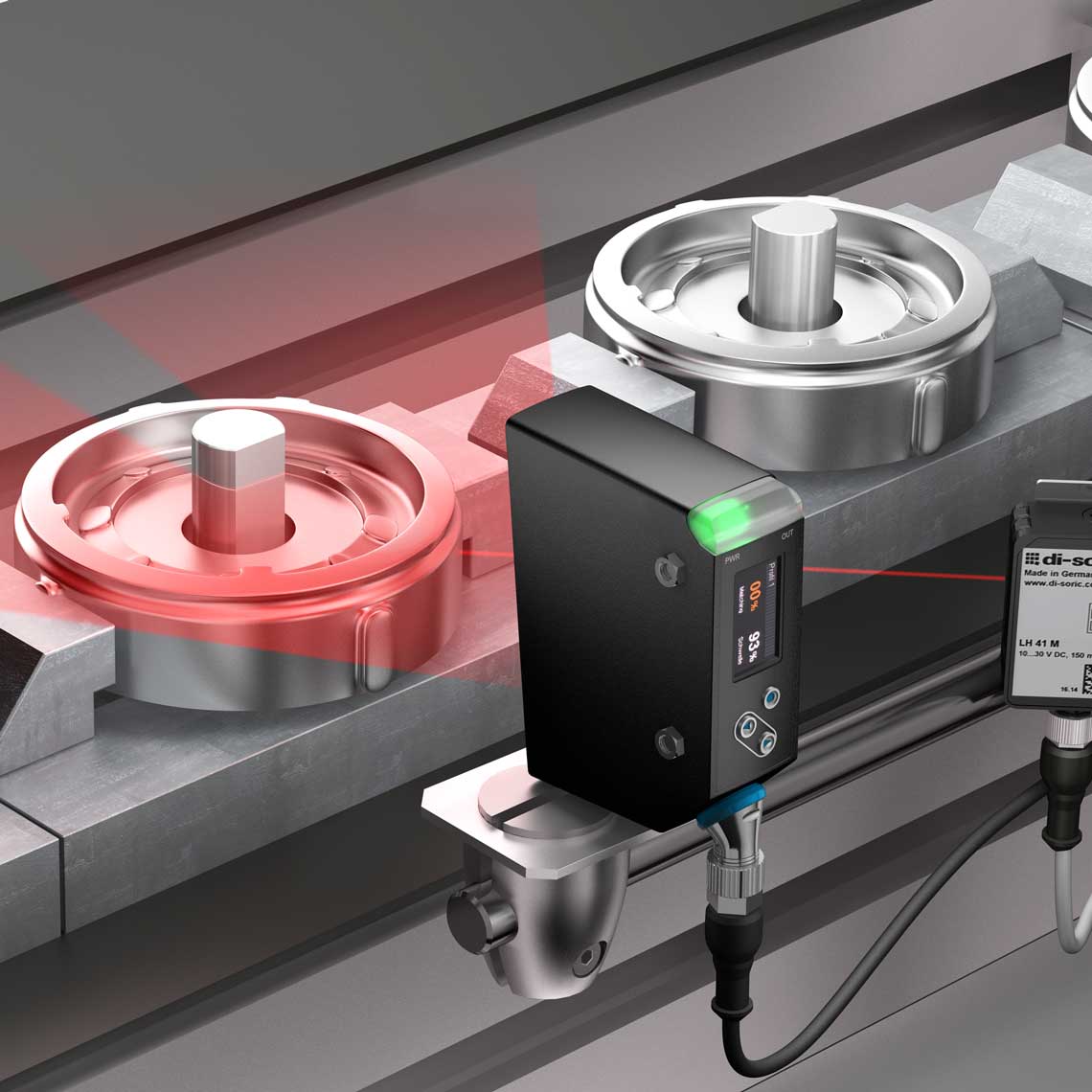

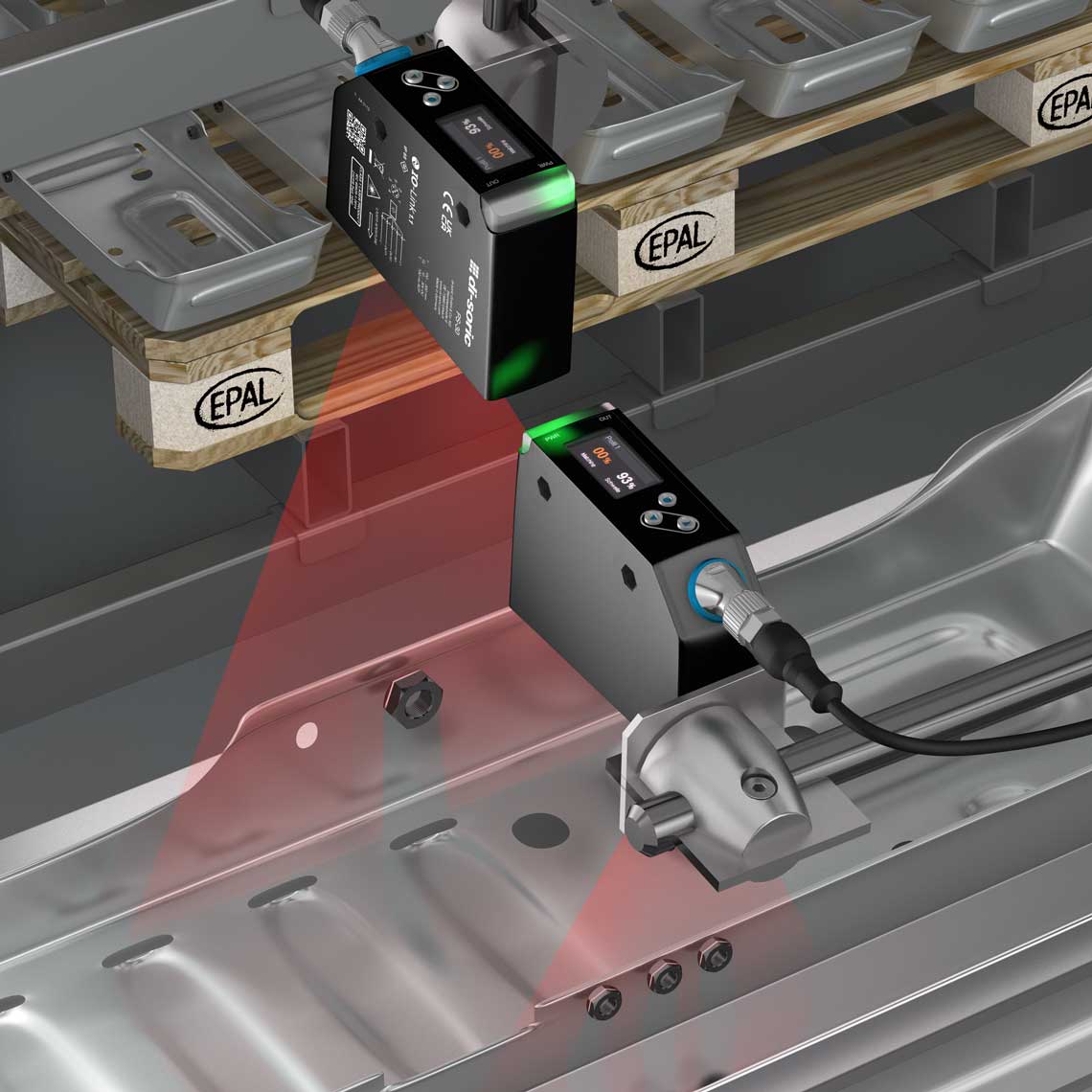

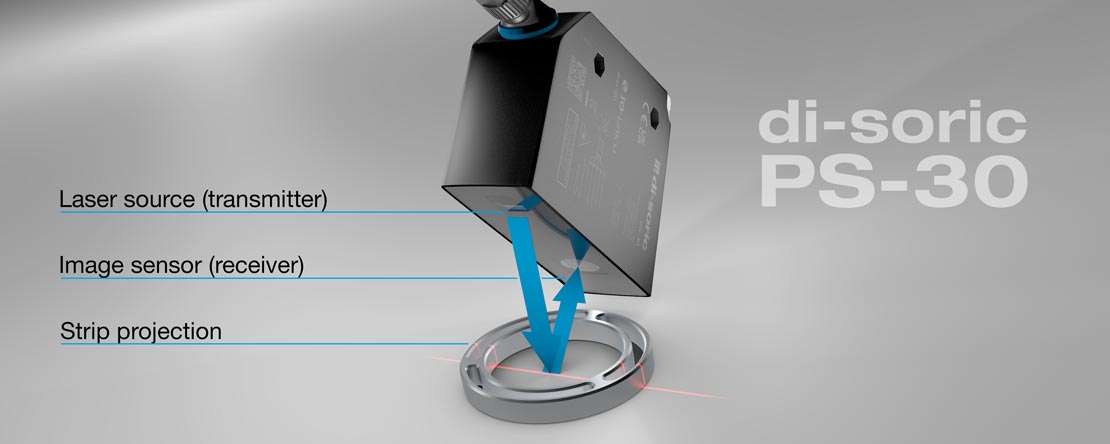

The optoelectronic PS-30 Profile Sensor is ready to use in just a few steps and captures profiles of various objects per laser line scan. Up to 10 target profiles simplify the inspection and measurement of changing objects on the same production line.

The PS-30 checks not only for the presence of an object, it also determines whether the actually intended component is used and correctly attached. Improve your product quality and increase your production efficiency with the PS-30 Profile Sensor.

Minimize costs and installation effort

- Can be used out-of-the-box:

Quick start-up with teach buttons and a display on the sensor - Ambient light immunity:

No shielding or external illumination necessary - Distance- and color-independent measurement:

High tolerance with object positioning

Higher production efficiency

- Up to 10 target profiles for simplified inspection of changing objects on the same production line can be stored

Sustained decrease in the rejection rate

- Simplified error analysis via IO-Link

Minimize costs and installation effort

through quick start-up, ambient light immunity and distance- and color-independent measurementIncrease production efficiency

with up to 10 target profiles for simplified inspection of changing objects on the same production lineSustainably reduce the rejection rate

through simplified error analysis via IO-LinkImprove your product quality

by ensuring correct assembly and processing

PS-30

Applications

Der PS-30 stellt sich Ihren anspruchsvollen Herausforderungen. Er erfasst Profile von Objekten und erkennt schon ab 0,5 mm Differenz zuverlässig ob Bauteile, Montagevorgänge Fräsungen oder Bohrungen vom Sollzustand abweichen.

Inline quality inspection

with the PS-30

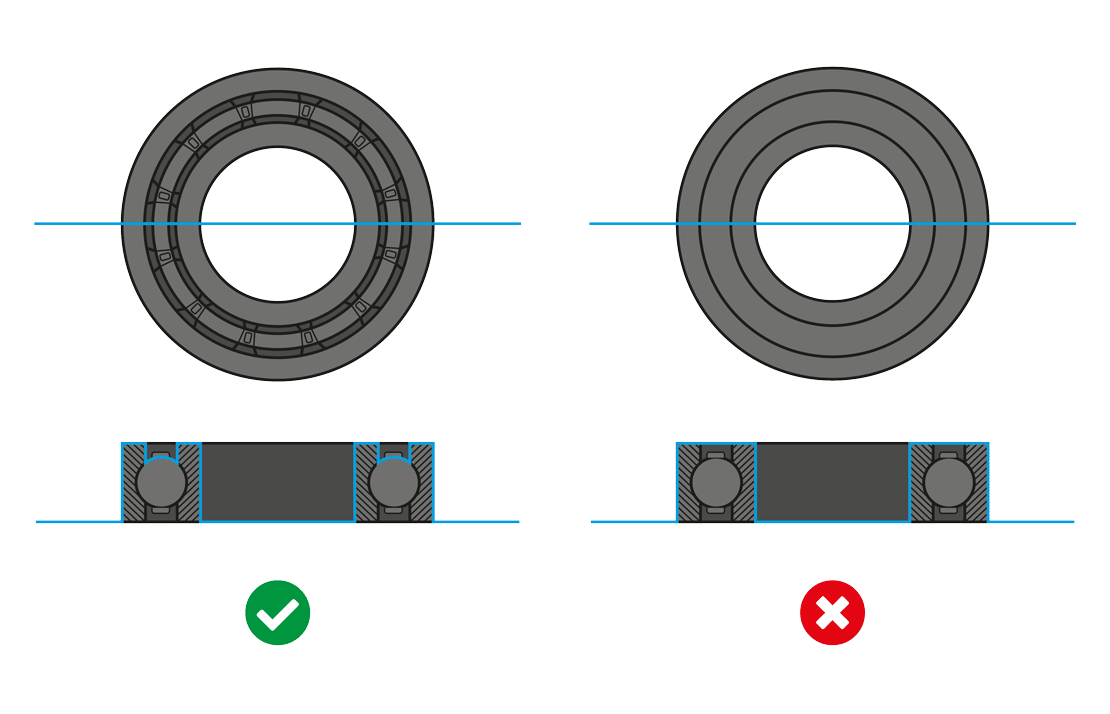

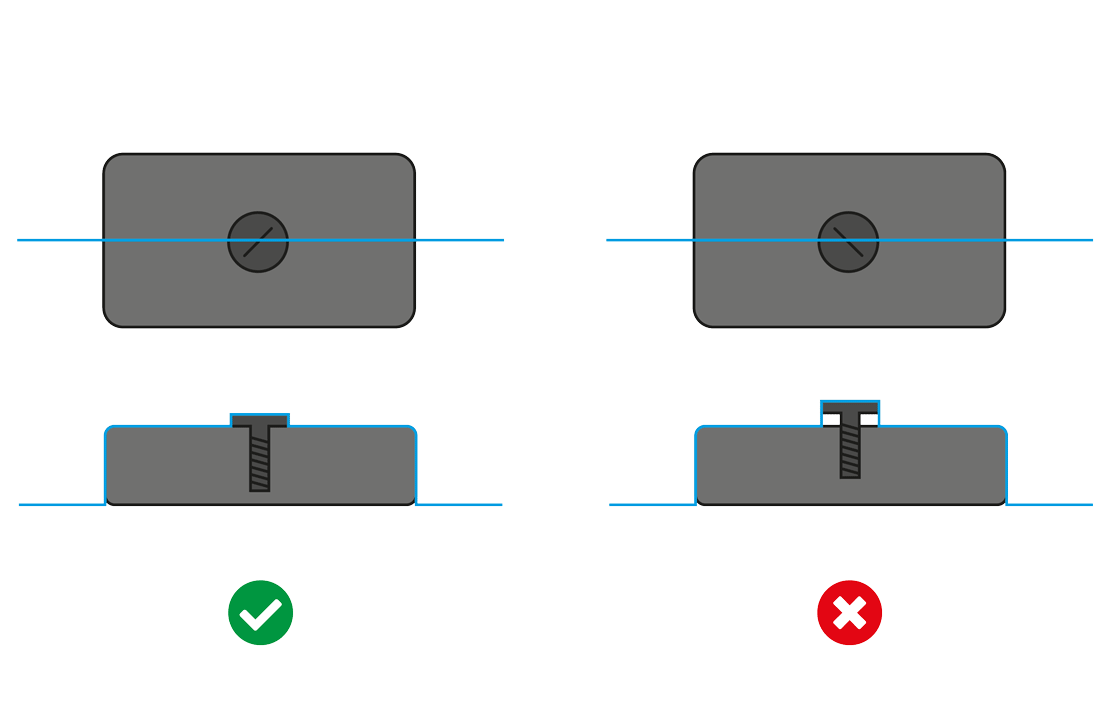

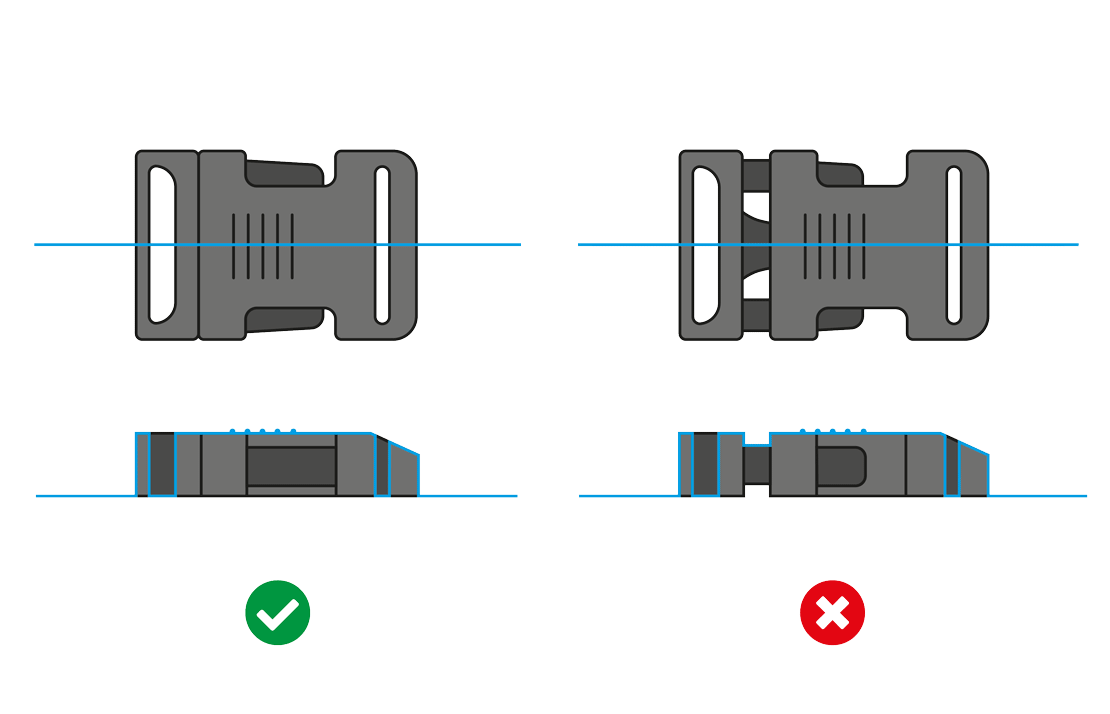

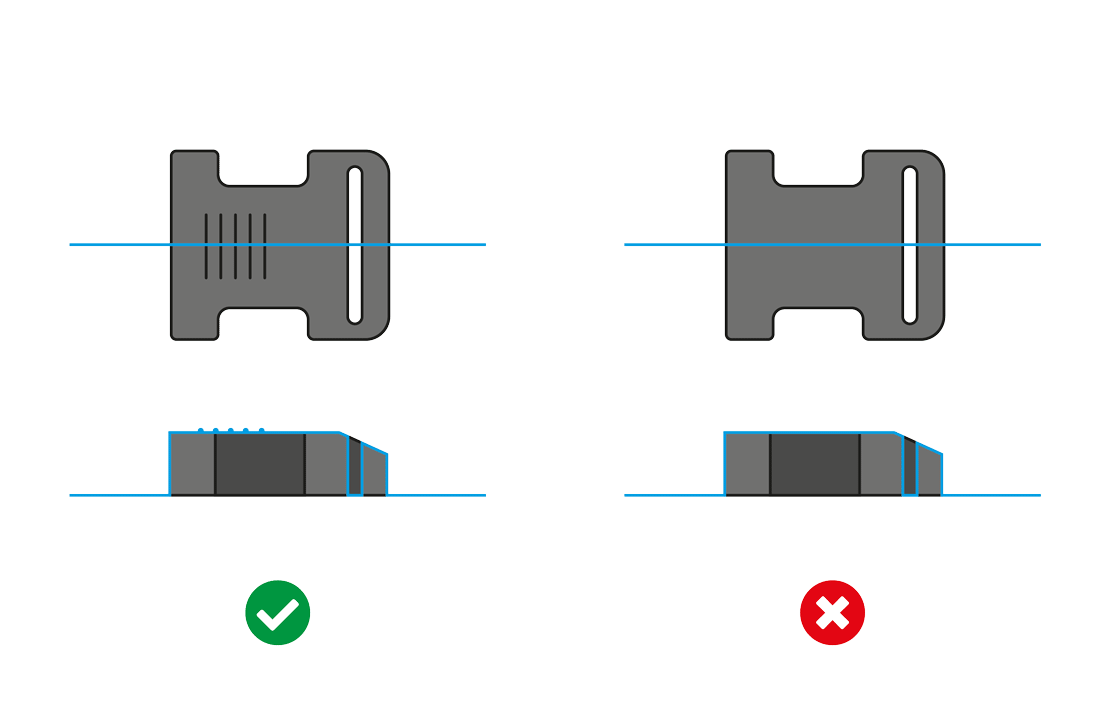

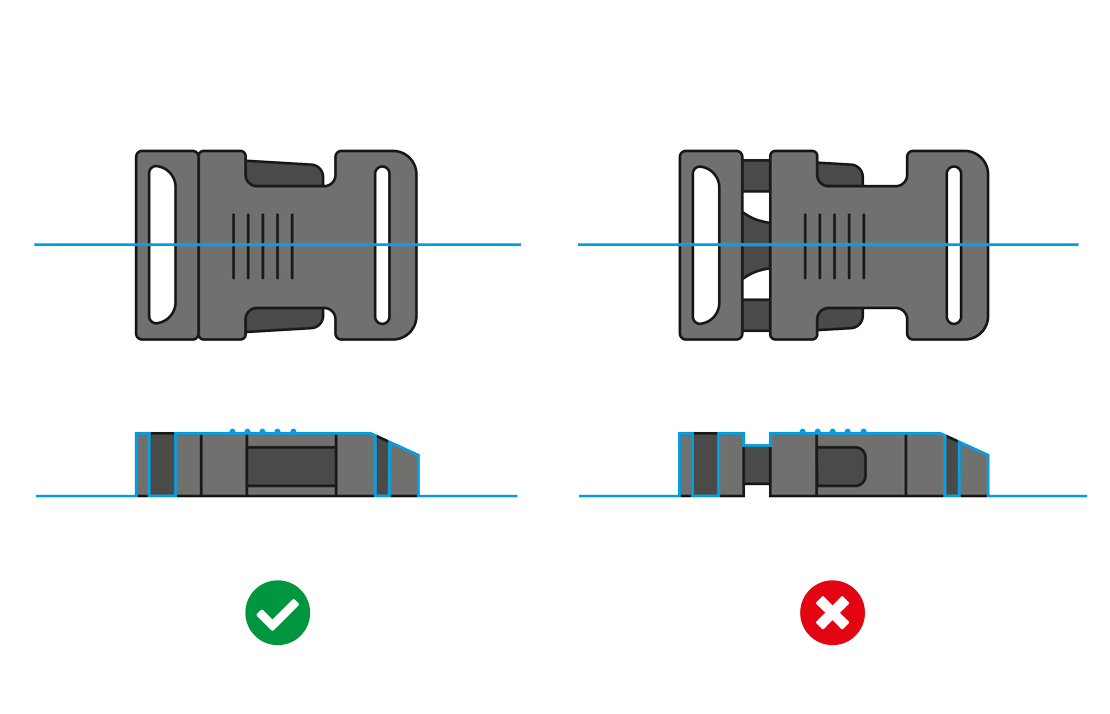

The PS-30 will meet your difficult challenges. By means of the light section method, it reliably detects the profile of objects and determines differences from 0.5 mm. Through the comparison of the actual height profile with the predefined height profile, a correct assembly, use, orientation and processing of the component can be checked.

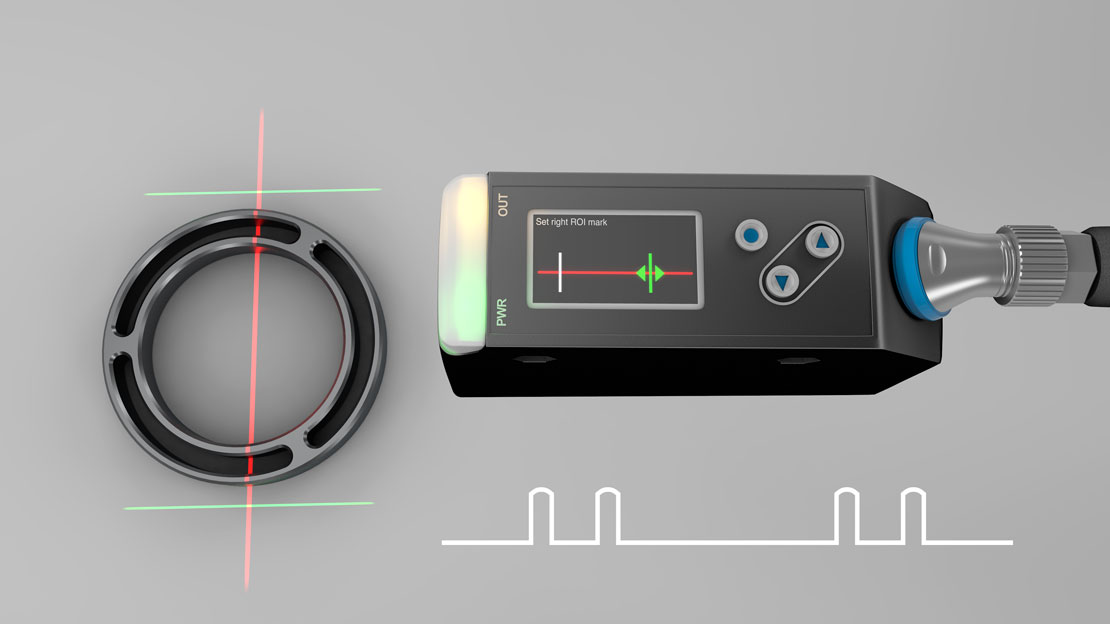

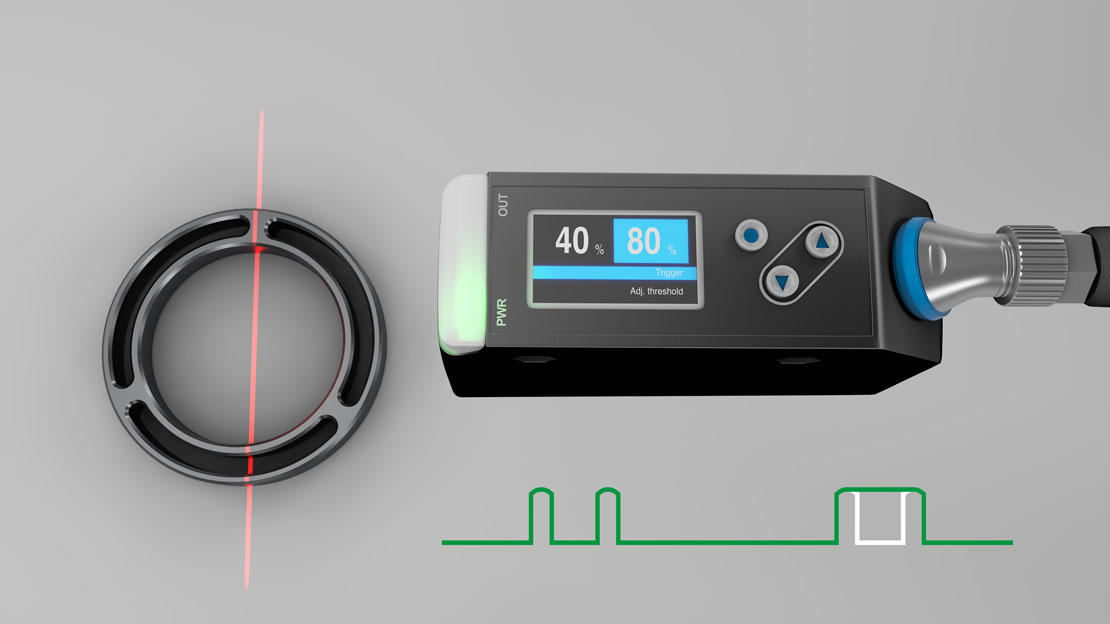

The inspection region can be delimited to relevant sections thanks to the region-of-interest function (ROI). Two green markers visualize the selected ROI on the laser line. By means of the ROI function, minimal gap deviations (e.g. in the case of unplugged plug connection) are also detected in addition to the presence or absence of the smallest components.

ROI markers on the component to be learned

with reference profile (white line)

Non-conforming component

(white: Reference profile, green: Live profile)

More Information

and accessories