Inductive

ring sensors, tube sensors,

and wire-break sensors

Ring sensors for reliably detecting

objects of all sizes

Our inductive ring sensors detect the smallest metallic parts that are conveyed in supply tubes for further processing. With its flawless shielding of the magnetic field, the IRSD series is particularly suitable for narrow spaces in a metallic environment or in environments where several sensors are installed adjacent to one another. The IRB series, on the other hand, is particularly well suited for easily detectable objects.

We have a reliable and practical solution for any application.

Tube sensors for flexible assembly on tubes

and pipes with different diameters

Tube sensors detect metallic objects in tubes, e.g. for accumulation monitoring and part counting, in a simple manner. Their conventional fastening method with cable ties allows the sensors to be assembled easily and their compact, robust design also makes them suited for use in harsh environments.

Wire-break sensors with high resolution

for the finest wires

Our wire-break sensors were developed to inspect wires for breakage points. With their very high resolution, they can detect wire breakages of the finest wires.

- Advantages, design and sizes

- Application examples

- Advantages, design and sizes

- Application examples

- Advantages, design and sizes

- Application example

- Advantages, design and sizes

- Application example

Inductive -

ring sensors

IRSD with IO-Link

Reliable detection of the smallest metallic objects in automated production

Our inductive ring sensors detect even the smallest metallic parts that are conveyed in supply tubes for further processing. The new generation of inductive ring sensors can be optimally adjusted to applications via IO-Link. They feature impressive multi-functionality. They make it possible to choose between NO/NC, static and dynamic switching principle, differential mode (push-pull), pnp and npn in a targeted manner.

In the case of parts that are fed very quickly, the integrated pulse stretching generates an output signal that can be easily analyzed. All devices from di-soric are reliably protected against overload, short-circuit and polarity reversal.

Features

- High resolution

- Static or dynamic operating principle can be set

- Pulse stretching adjustable

- NO/NC can be set

- PP/PNP/NPN switchable

- Short response time

- Intelligent teach-in process

- Remote Teach via IO-Link or pin 2

- Extended diagnostic functions via IO-Link

- 2 switchable working frequencies

- High IP67 protection type

- M12 connection technology ideal for industrial applications

Highlights

- Flexible integration thanks to a compact design and minimal assembly distances

- Flexible adjustment on the device, remotely via IO-Link or via its digital input

- Optimal adaptation for process-reliable operation

- Suited for use in harsh environments thanks to robust housing and high IP protection type

- Integration of sensors in the smallest spaces

- Small inventory through a reduction in variants

- Extended information on the machine process via IO-Link

Supportive, smart IO-Link functions of the IRSD series

Diagnostic function stability

Shows when object detection is impaired, for example due to soiling.

After cleaning and once sufficient functional reliability is established, the status bit is reset.

Working frequency switching

This function prevents mutual influencing of sensors assembled directly adjacent to one another.

Autoteach / Intelliteach

This function is available for teaching in falling or quickly passing objects. It enables the automatic teach-in of objects and the intelligent concealment of environmental conditions.

Highest degree of flexibility

during integrationThrough a variety of setting options such as switching of NO/NC or static and dynamic, the sensors can be set perfectly to the most diverse applications.

Large variety

for a large number of applications

16 variants in 8 sizes

with the detection ranges from a minimum of 6 mm to a maximum of 50 mm ensure that the IRSD can find their place in any ring sensor application. All sizes have IO-Link and are available with or without potentiometer. All sizes have IO-Link and are available with or without potentiometer.

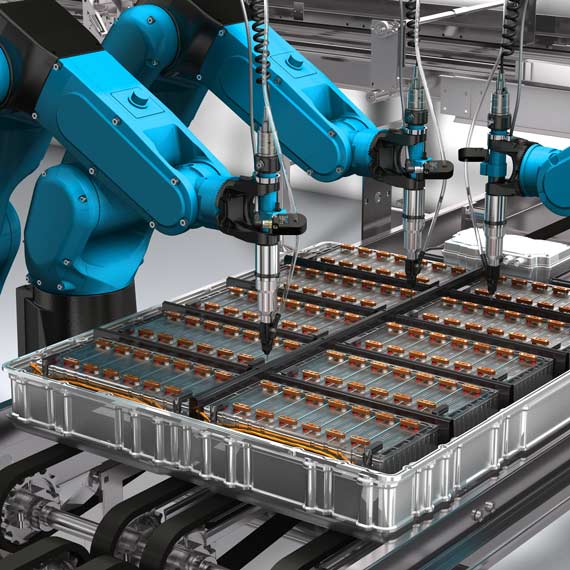

Application examples

IRSD

Inductive

ring sensors

IRB Standard

Simple integration and reliable detection

The inductive ring sensors of the IRB Standard series in the sizes Ø 10.1 mm to 27 mm detect the smallest metallic parts. They can be put into service quickly and have no adjusting elements. These sensors work according to the static operating principle and exhibit a short response time.

Features

- Short response time

- No teaching necessary

- High IP67 protection type

- M12 connection technology ideal for industrial applications

Highlights

- May be used in harsh environments

- Fixed and simple commissioning

- Resistant to dirt

- Protected against manipulation

Application examples

IRB Standard

Inductive

tube sensors

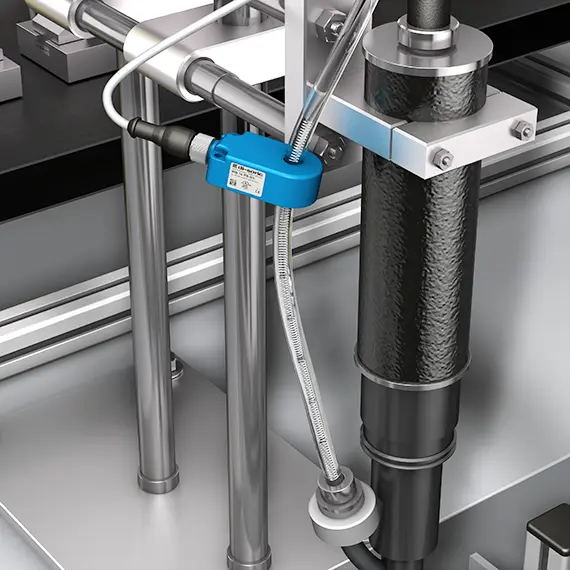

IS and ISDP

For simple detection and counting of objects in tubes

Tube sensors are perfectly suited for flexible assembly. Their tasks are detecting parts and part counting.

The static and dynamic evaluation principle enables simple accumulation monitoring to be implemented.

The compact sensors can be adapted quickly to various tube cross-sections –

without disassembly of the supply tube thanks to their conventional fastening system.

Features

- High resolution

- Short response time

- Simple fastening concept

- Static or dynamic operating principle

- Connection technology ideal for industrial applications

with M8 plug or cable with M12 plug connector - High IP67 protection type

- Low weight

Highlights

- Simple integration

- Flexible assembly on tubes with different diameters

- Protected against manipulation

- Resistant to dirt

Application example

IS

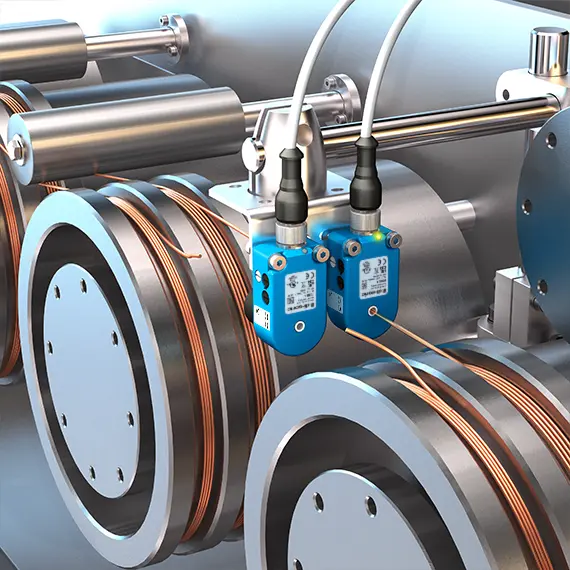

Inductive

wire-break sensors

IRDB and IRDBD

Safe detection of the smallest parts and wire breakages

The inductive wire-break sensors of the IRDB and IRDBD series are used for detecting wire breaks. The sensors are available in the sizes Ø 4 mm and 6 mm. They can be commissioned quickly and can be regulated via their 3 potentiometers.

These sensors work according to the static or dynamic operating principle and exhibit a short response time.

Features

- Very high resolution

- Short response time

- Pulse stretching adjustable

- NO/NC can be set

- Static or dynamic operating principle

- Wear-resistant ceramic insert

- M12 connection technology ideal for industrial applications

- High IP67 protection type

Highlights

- Detection of the smallest objects

- Extended maintenance intervals due to durable materials

- Flexible integration

- Suited for use in harsh environments

Application example

IRDB

Sample order / Appointment

Download

Order and test samples now!

Test our ring and tube sensors and many other solutions free of charge and see for yourself for 28 days.